Sustainability

Transparent about sustainability

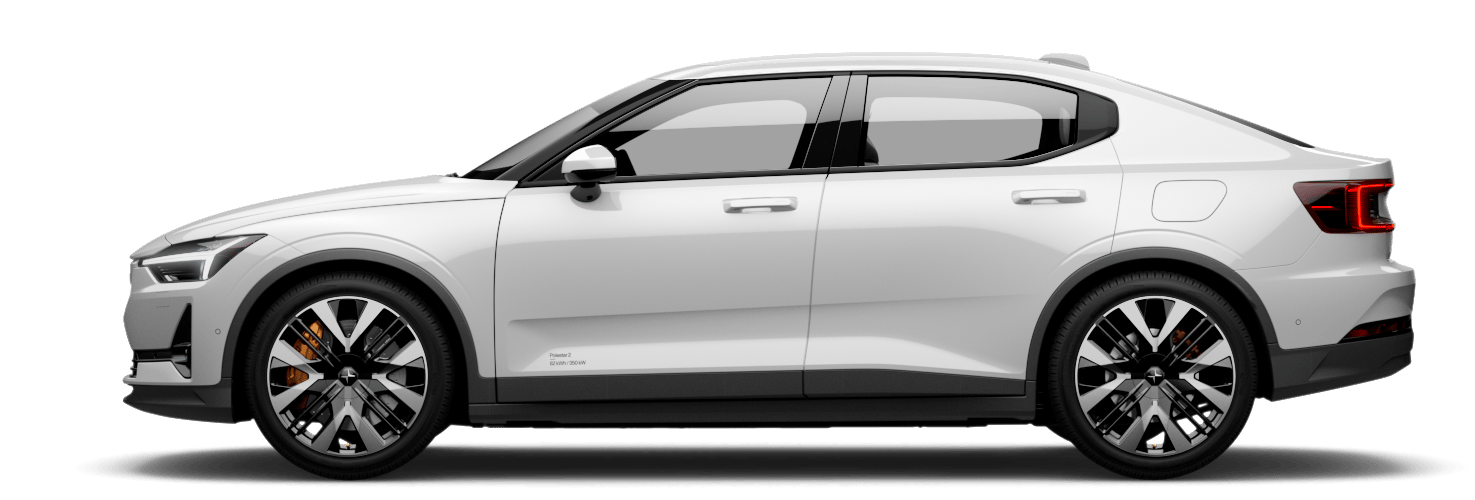

This Product Sustainability Declaration is a high-level presentation of Polestar 2’s sustainability credentials. It aims to provide consumers with transparent information to enable them to make informed, ethical choices.

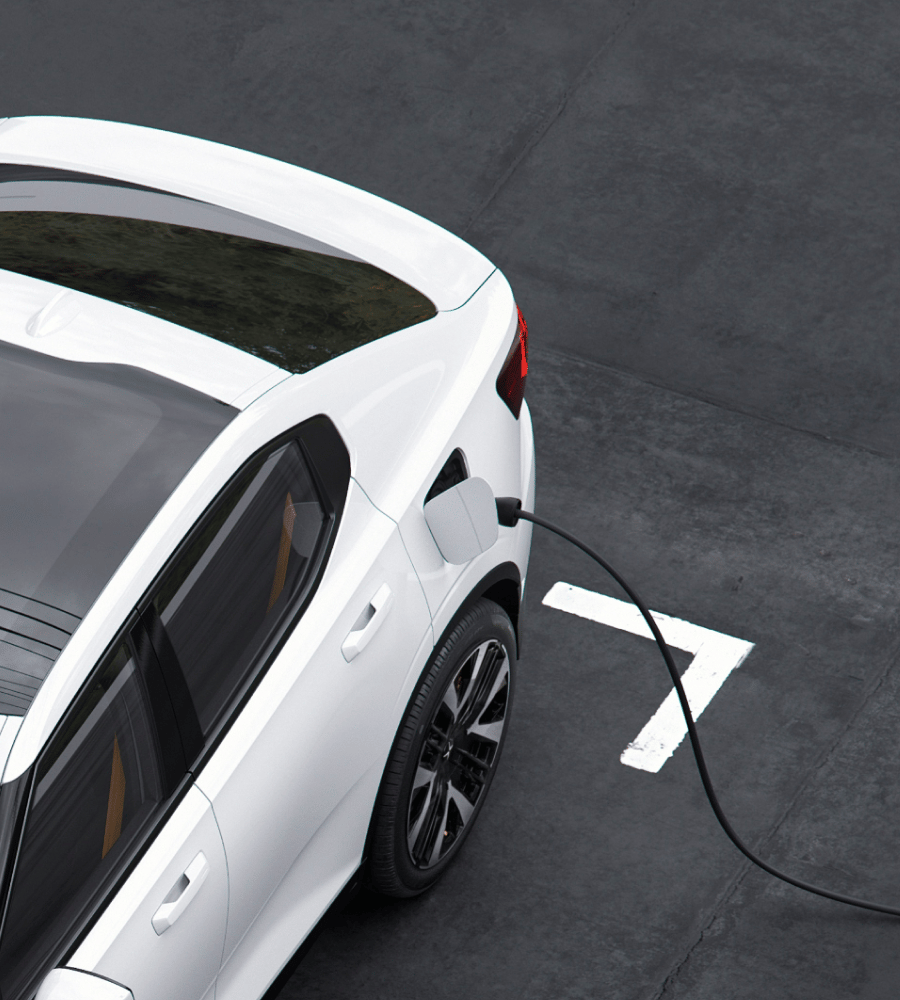

Carbon footprint

We’re continuously revisiting the materials and processes that go into the manufacture of Polestar cars to lower greenhouse gas emissions from the cradle-to-gate phase of their life cycles. You can reduce total footprint during the in-use phase by charging with renewable energy.

More about climate neutrality

Polestar 2 life cycle

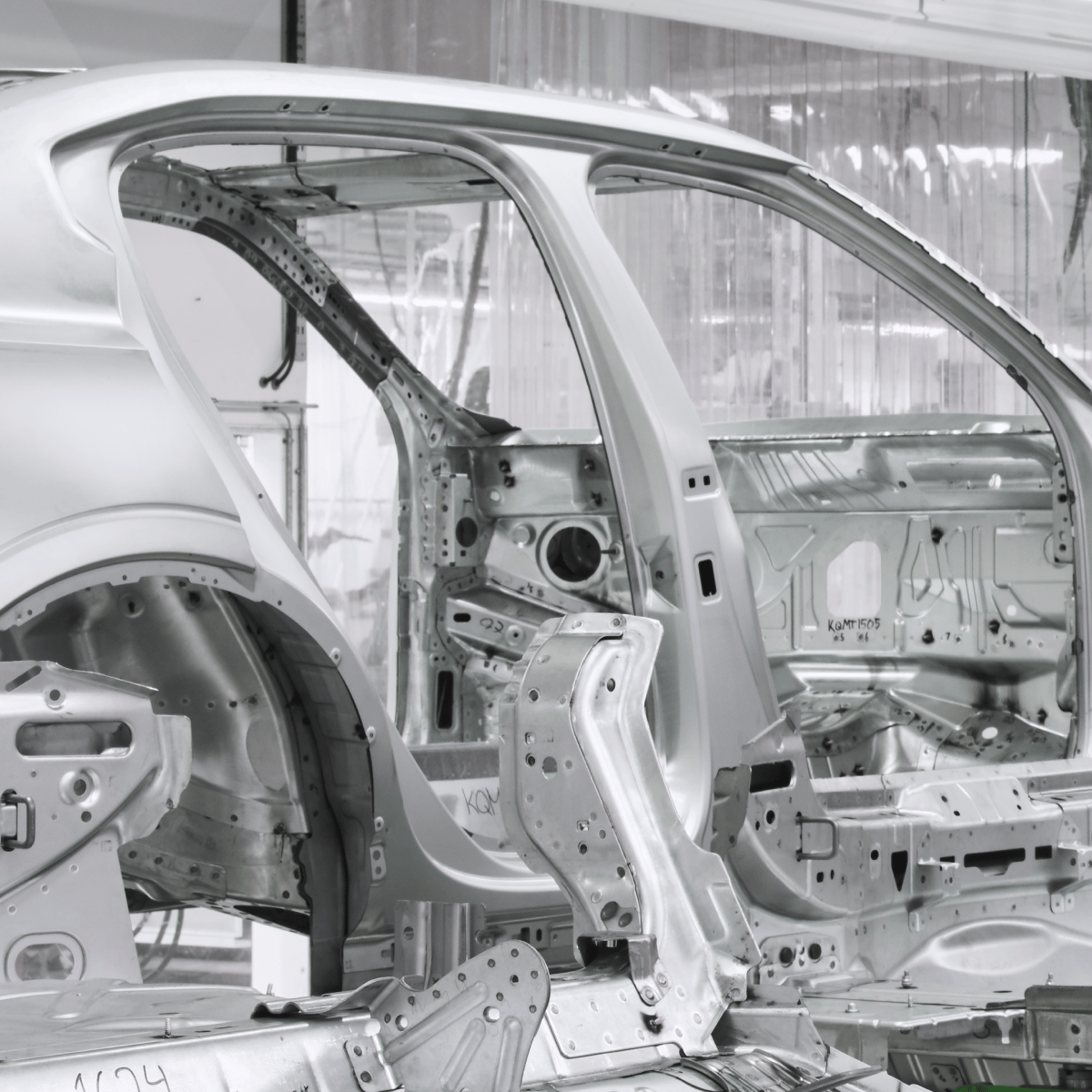

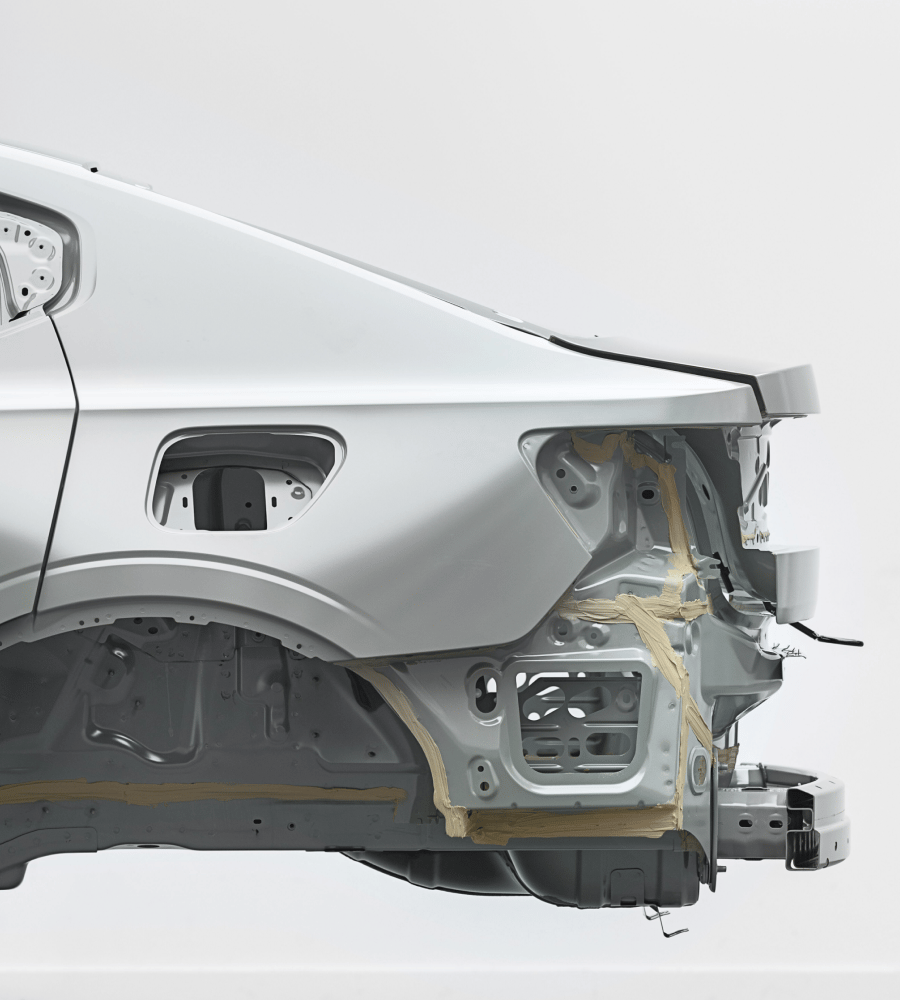

Materials production

From aluminium and steel to plastics, each material category contributes to Polestar 2’s overall carbon footprint, as does the electricity mix used in material production and refining. We aim to continuously reduce the carbon impact and further improve the accuracy of our footprint calculations.

Polestar 2 life cycle

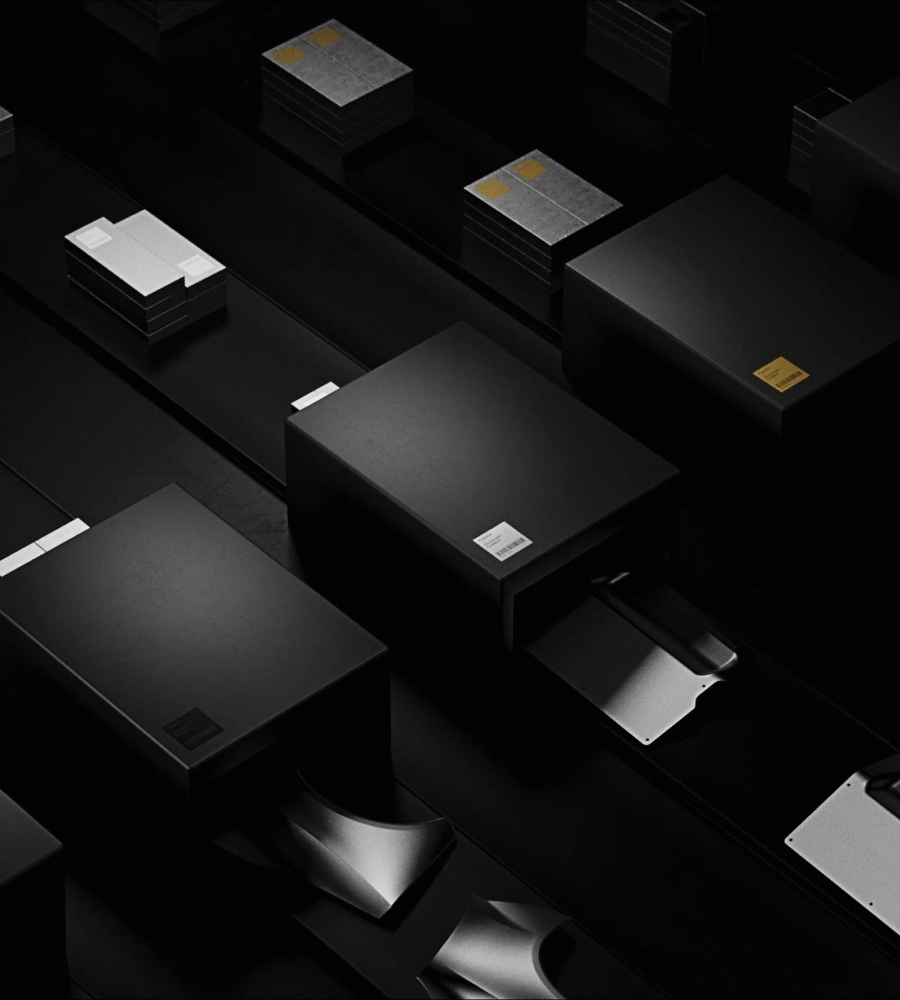

Li-ion battery modules

Several factors contribute to the battery’s carbon footprint, from the energy used for cell production to the aluminium used in the battery casing. We push our suppliers to reduce the carbon footprint of the battery modules they supply.

Polestar 2 life cycle

Manufacturing and logistics

Polestar 2 is produced in Volvo Cars’ plant in Taihzou, a manufacturing facility powered by 100% solar energy. Using entirely renewable electricity reduces the carbon footprint by 0.5 t CO₂e per car.

Polestar 2 life cycle

Use phase

After a Polestar 2 leaves the factory, its owner can make a significant difference to its overall carbon footprint by charging with renewable energy wherever possible.

Polestar 2 life cycle

End of life

Polestar 2 is 85% recyclable, and a majority of components can be reused or remanufactured. Increasing components’ lifespans in this way can reduce both waste and the CO2 emissions produced by making all-new components.

Cradle-to-gate carbon footprint

These figures represent the CO₂e emissions of Polestar 2 in the cradle-to-gate phases of the car’s life cycle. Battery upgrades in a majority of markets¹, in addition to drivetrain upgrades, have impacted overall vehicle carbon footprint.

Standard range Single motor

- Materials production

- 15.4 t

- Battery modules

- 5 t

- Manufacturing and logistics

- 1.6 t

- Total

- 22 t

Long range Single motor

- Materials production

- 14.9 t

- Battery modules

- 5.9 t

- Manufacturing and logistics

- 1.6 t

- Total

- 22.4 t

Long range Dual motor

- Materials production

- 15.7 t

- Battery modules

- 5.9 t

- Manufacturing and logistics

- 1.6 t

- Total

- 23.1 t

Battery carbon footprint

Thanks to improved cell chemistry, CO2e emissions for Polestar 2 Long range Single motor and Long range Dual motor in most markets¹ have been reduced by 1.1 tonnes, down from 7 to 5.9 tonnes per car.

Circularity

From design and materials, to sourcing and assembly, to use and reuse. Polestar 2 represents another step toward full, closed-loop circularity in the production and use of electric cars.

More about circularity

Material innovations

WeaveTech upholstery

WeaveTech is a 100% vegan, PVC-based leather alternative that’s both dirt- and moisture-resistant. Its high-end production process reduces the amount of chemical plasticiser from the standard 35-45% to just 1% on average.

Used in Polestar 2 upholstery.

Material innovations

Black and light ash wooden deco

Available in two colour options, the distinctive look of the wooden deco comes from the wood’s grain, which is treated to reduce material waste and emphasise its natural beauty.

Used in Polestar 2 deco panels.

Traced materials

Tracing materials back to their origin is the first step towards achieving more responsible sourcing and production processes. We aim to have more material tracing in place for each new model.

Polestar works with blockchain partner Circulor to trace battery risk minerals such as cobalt and mica. We collaborate with Bridge of Weir to do the same for leather.

More about transparency

Responsibly sourced materials

Nappa leather

The hides used for the optional leather upholstery originate from farms in countries rated with the highest global standard by the Animal Protection Index. They come sourced via Bridge of Weir and are certified chrome-free.

Used in Polestar 2 upholstery.

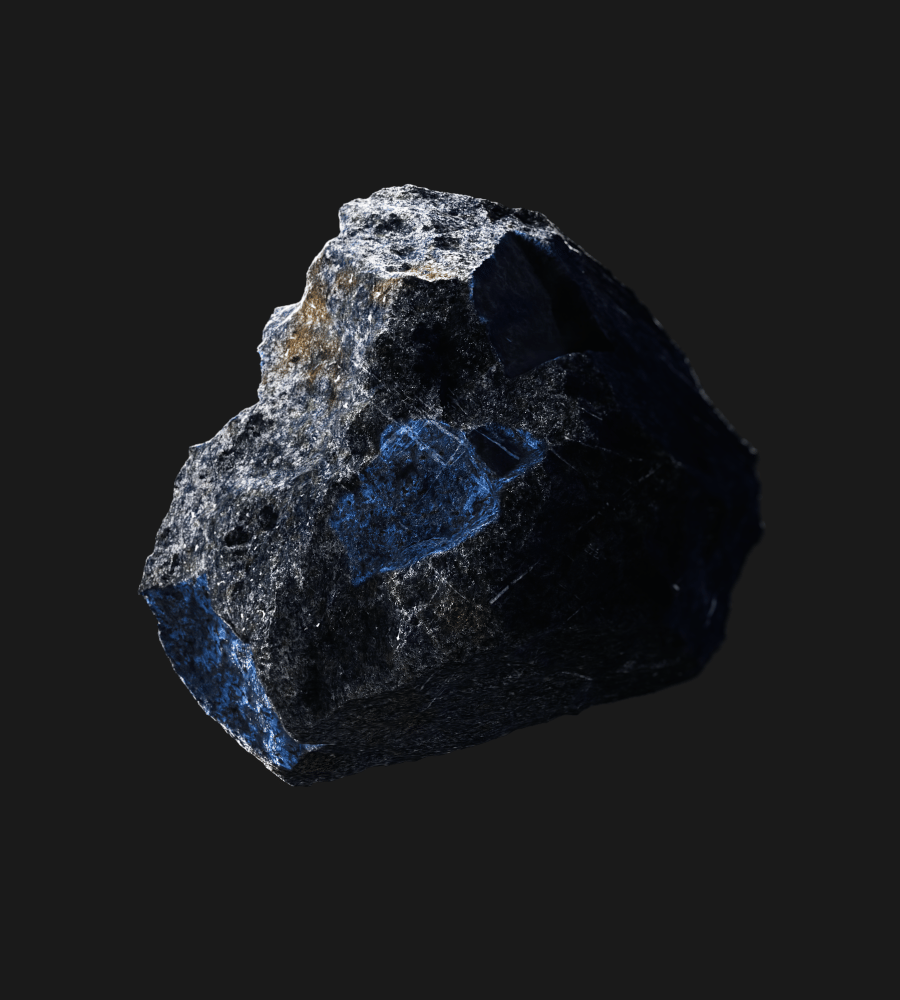

Blockchain traced risk materials

Cobalt

Cobalt is a hard metal used to extend battery life in Polestar 2’s lithium-ion battery pack. Major risks associated with mining cobalt include forced labour and child labour, corruption, weak rule of law, high-intensity conflicts, and pollution from hazardous materials.

Blockchain traced risk materials

Mica

Mica is a group of silicate minerals used in the Polestar 2 lithium-ion battery pack as a thermal barrier to hinder fire, and improve safety and robustness. Major risks associated with mining mica include child labour and forced labour, weak rule of law, corruption, artisanal, and small-scale mining.

3TG

Tin, tantalum, tungsten and gold, also known as ‘conflict minerals’, have a wide range of applications in Polestar 2’s construction and electronics. In politically unstable areas, mineral trade can be used to finance arms groups, fuel forced labour and other human rights abuses, and support corruption and money laundering. 3TG is traced via Conflict Mineral Reporting, which promotes smelters verified to conform with the Responsible Minerals Assurance Program (RMAP).

Polestar and sustainability

Polestar is determined to improve the society we live in, using design and tech to accelerate a widespread shift to sustainable electric mobility. Find out more about how we’re getting there.

More about sustainabilityMore about Polestar 2

- Battery capacity and charging speed for Long range Dual motor remains 78 kWh and 155 kW DC for China and Korea. The Long range Single motor version in Korea also retains a 78 kWh battery and 155 kW DC max charging speed.

- Visuals are for illustrative purposes only.