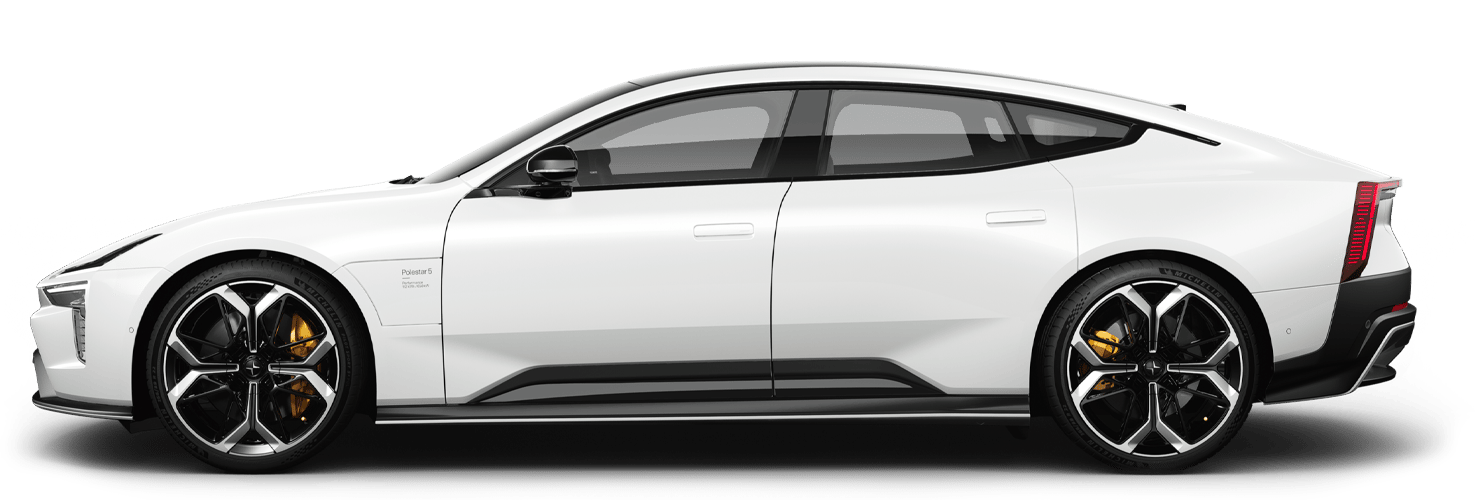

Polestar 5 Sustainability credentials

This is a high-level presentation of the Polestar 5’s sustainability credentials, aimed at providing transparent information to empower informed decision-making.

This is a high-level presentation of the Polestar 5’s sustainability credentials, aimed at providing transparent information to empower informed decision-making.

Cradle-to-gate refers to the environmental impact assessment of a car’s life cycle from the first raw material extraction to it reaching the customer. Every step of the production process is continuously evaluated to measure and minimise its carbon footprint.

Cradle-to-gate refers to the environmental impact assessment of a car’s life cycle from the first raw material extraction to it reaching the customer. Every step of the production process is continuously evaluated to measure and minimise its carbon footprint.

From aluminium and steel to plastics, each material category contributes to Polestar 5’s overall carbon footprint, as does the electricity mix used in material production and refining. We aim to continuously reduce the carbon impact and improve the accuracy of our footprint calculations.

Factors in the battery’s carbon footprint calculation range from mining operations, to the energy used for cell production, to the aluminium in the battery casing. We aim to further reduce battery carbon footprint with future models and iterations of Polestar 5.

The Polestar 5 production is split between two manufacturing plants. The component build takes place in Chongqing, China and final process is completed in Wuhan, China. In Chongqing, where the most energy intense processes occur, the plant runs on 100 % renewable energy. Logistics services, including parts delivery and shipping of finished cars are accounted for in our carbon footprint reporting.

Cradle-to-gate CO₂e emissions¹

Polestar 5

Material production

14.4t

Battery modules

6.9t

Manufacturing and logistics

2.5t

Total²

23.8t

Carbon footprint proportions¹

Aluminium

35%

Polymers

9%

Battery modules

33%

Electronics

5%

Steel and iron

11%

Other materials

6%

In order to reduce the battery carbon footprint of the Polestar 5, its battery cell modules are manufactured using renewable electricity, which also extends to the production of anodes, cathodes, and copper foil.

The chassis of the Polestar 5 is made entirely of bonded aluminium, a material traditionally reserved for limited-edition performance cars. 83% of the aluminium secured for the Polestar 5 comes from smelters utilising renewable electricity while 13% is recycled. This mitigates over 14 tCO₂e compared to using the standard aluminium available in China.

Cradle-to-grave evaluations consider the full span of a car’s existence, including life cycle steps that extend past the cradle-to-gate evaluation. Our Life Cycle Assessment (LCA) quantifies the climate impact of every stage of the manufacturing, use and end-of-life of the Polestar 5. This includes the raw materials, first drive, everyday charging, maintenance, and more, all the way up to its final recycling.

Cradle-to-grave evaluations consider the full span of a car’s existence, including life cycle steps that extend past the cradle-to-gate evaluation. Our Life Cycle Assessment (LCA) quantifies the climate impact of every stage of the manufacturing, use and end-of-life of the Polestar 5. This includes the raw materials, first drive, everyday charging, maintenance, and more, all the way up to its final recycling.

On the road, Polestar 5 drivers can significantly reduce the car’s overall carbon footprint by charging it with renewable energy sources such as solar or wind.

As part of creating a complete LCA report, the maintenance of Polestar 5 is considered. This includes changes of tyres, wiper blades, brake discs, brake pads, and more.

Over 85% of the Polestar 5 is recyclable, whereas several components can be reused or remanufactured. Increasing components' lifespan in this way can reduce waste and avoid the CO₂ emissions associated with making new components.

More on our key drivers

Circularity

We continuously aim to make cars that last longer, with more circular materials, as we move closer to a goal of full circularity.

Read moreClimate neutrality

Discover the steps we’re taking to meet our defining goal of becoming a fully climate-neutral company by 2040.

Read moreInclusion

Within Polestar, equal opportunities and a culture of open communication. Within our supply chain, human rights above all.

Read more