More than the sum of its parts: BST edition 270

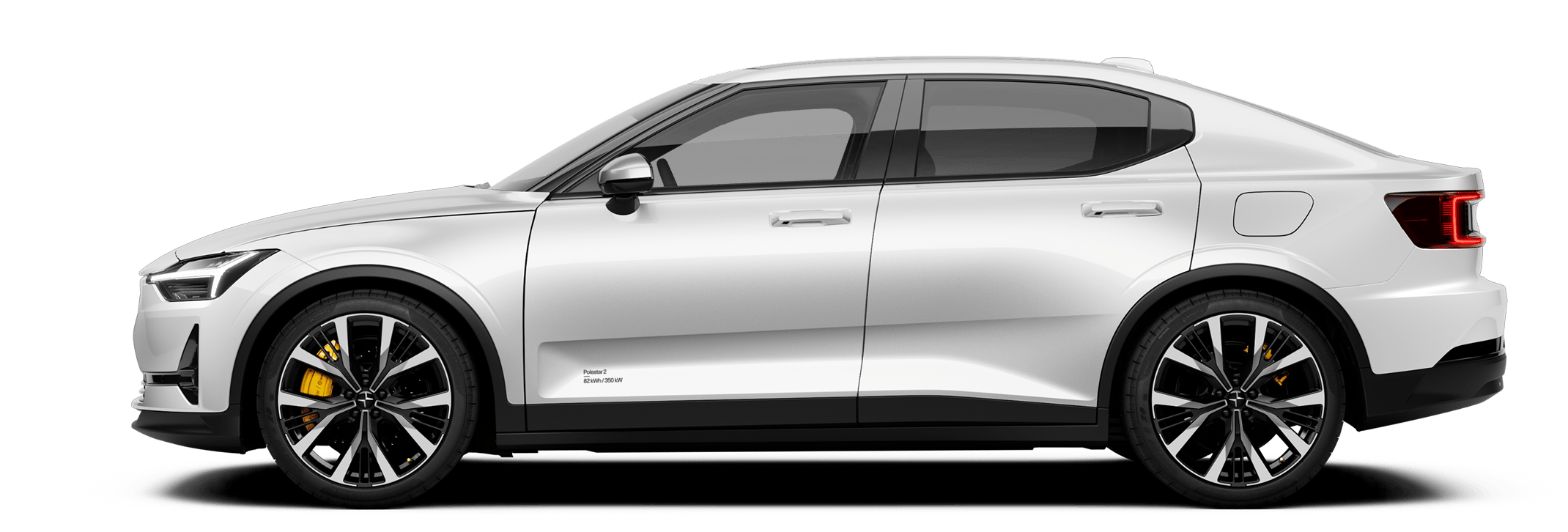

Working with others comes with a wealth of advantages. The sharing of expertise, lessons learned, and creating things that would never have been possible while working alone. The Polestar 2 BST edition 270 is one such thing. A passion project brought to you by the best in the business.

Nestled in the Andalusian hills, the Circuito Ascari stretches 5.4 km and offers drivers everything from adrenaline-inducing chicanes to picturesque views of the Spanish countryside. We invited our partners Öhlins, Brembo, and Pirelli to the famous Circuito Ascari for a test drive of the Polestar 2 BST edition 270: our limited-edition Polestar 2, created to push the boundaries of electric performance.

Our partners’ combined efforts have made the BST edition 270 possible. During the week, we had the opportunity to sit down with their representatives and talk about what makes collaborating with Polestar unique.

Brembo are world leaders in braking systems. They bring technical expertise and experience, supplying the braking systems for Formula 1 and MotoGP as well as the larger automotive industry. Although their history lies in supplying brakes for vehicles with internal combustion engines, Brembo have recognised the shift towards electric. Uwe Hein, Head of System Sales and Marketing at Brembo, noted that working with Polestar is defined by its focus on sustainability and design. “We have developed smaller callipers and disks which require lower raw material”, he says. “This focus on sustainability matches with the ethos of Polestar”. But the unique challenge when working with the BST edition 270 was the design of the brake calliper. “It was important because the coloured calliper is a very visible part of the car”, Hein says. In the end, Brembo delivered a golden brake calliper which, in Hein’s words, “combines Italian beauty with Swedish design”

01/04

For more than 40 years, Öhlins have supplied the automotive industry with elite suspension technology. Apart from collaborations with Yamaha, Ducati, and BMW, their dampers can be found in the Polestar 2 performance pack, and of course in the BST edition 270. Henrik Schiölde, R&D engineer from Öhlins, emphasised the long history Öhlins and Polestar share. Öhlins have supplied our cars with their world-class dampers from the beginning. “We know each other so well, which makes the work so much easier”, Schiölde states. “We have formed strong personal relationships, so sometimes a handshake or a simple phone call is enough to get a project started”, he chuckles. When asked what separates Öhlins from its competitors, Schiölde highlighted the enthusiasm and curiosity of the employees. “Everyone in the company has a deep interest in cars and motorcycles – regardless of whether you are a receptionist or tuning dampers”. According to Schiölde, it is this drive and passion which motivates and pushes the company forward.

The third piece of the puzzle is Pirelli. They have been around since 1872 and are among the world’s largest tyre producers for both race and consumer cars. Their focus is on creating tyres with the highest levels of performance, safety, quietness, and adherence to road surface. Speaking to Mauro Alpegiani, R&D Tyre Engineer at Pirelli, it becomes clear that developing a tyre is no easy feat; changing one aspect to improve quietness may have a devastating effect on performance. When asked what has given Pirelli their success throughout the years, Alpegiani underlined the importance of collaboration. “We think that co-developing together with OEMs gives us a huge advantage, since it allows us to get the best out of the car”, he says. This focus on co-development defines the project of creating the custom-made tyre for the BST edition 270. “We trust each other and try to improve together”, Alpegiani notes. In addition, Alpegiani noticed an open-mindedness and curiosity while working with Polestar. “Many times, when you work with OEMs you run into walls, but with the Polestar 2 we played a lot, tried different ideas, and honestly had a lot of fun. I haven’t found this anywhere else” he says.

As much as cars need suspension, tires, and brakes, the best cars require passion, expertise, and curiosity. It’s precisely these attributes that we share with our partners which has allowed us to create a car which truly pushes the boundaries of electric performance.