Journal 5

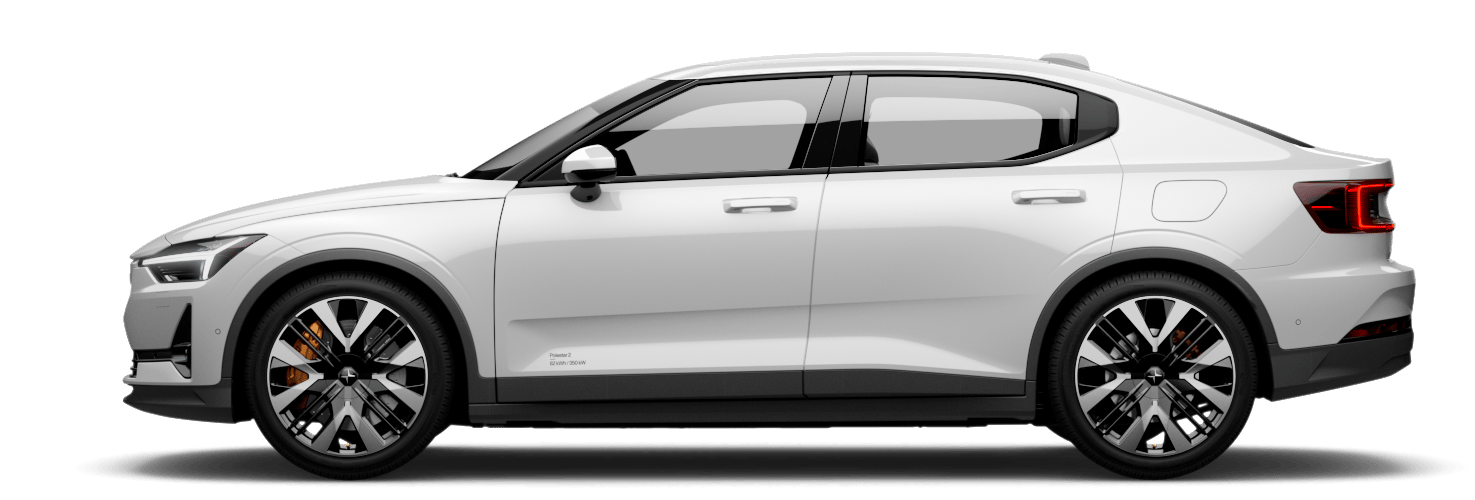

When the Polestar 1 was revealed to the world last year, the reaction was overwhelming. Complete with its concept car looks, the first car from Polestar left no one in any doubt. This was not a test.

The perfect balance

This was an exciting new car company with big ambitions. Low, sleek and with a captivatingly athletic stance, everyone behind the scenes at Polestar were determined that those beautiful proportions would find their way onto the very first production version in 2019.

But staying faithful to the original design would mean using some advanced materials. Carbon fiber would not only be needed to maintain the slender proportions and keep the weight down, but also to meet those ambitious performance figures.

But how challenging would the material prove to be? Would designers and engineers be able to find the right balance of materials and would the advantages of carbon fiber really be worth it?

We interviewed Zef van der Putten, Principle Engineer on Polestar 1, to find out more.

Perfecting the use of carbon fiber

Carbon fiber is still considered exclusive, expensive and lightweight, but that makes it the perfect choice for a car that guarantees so much cutting-edge technology, future thinking and performance.

Having first made an appearance in Formula 1 some thirty years ago, carbon fiber was complex to work with, but harness its properties and the advantages were huge. What was obvious was that it was significantly lighter and stronger than other materials. Soon every team was using it and so were high-end performance car manufacturers. Its reputation as a serious performance-enhancing material was sealed.

Fast-forward to the present day and carbon fiber body structures have become the embodiment of cutting-edge, high-tech performance – reducing weight, increasing performance, lowering the car's center of gravity and improving torsional stiffness.

And this is confirmed upon closer inspection of the car. A simple walk around reveals some serious engineering pedigree. The upper body, including the doors, front fenders, hood and trunk lid are made of carbon-fiber reinforced polymer (CFRP). And then there's that low roofline that has mesmerized so many people.

"With a standard steel roof construction," says Zef, "all of these sections would have been bigger – the roof higher and the windows more upright. Making the whole roof construction out of carbon fiber enabled us to realize that low, elegant roofline."

The Dragonfly (Odonata: Anisoptera) Nature's answer to strength and agility. Honed through relentless evolution.

Your eye automatically follows the line from A-pillar to C-pillar. But what you don't see is what lies beneath: a super stiff prefabricated carbon fiber tube that is baked into the two half shelves of the carbon-fiber pillar construction. They are linked laterally by slim, light and ultra-stiff carbon fiber cross-sections.

But that's not all. The SPA platform is heavily reworked with 320 mm (12.6 in) removed from the wheelbase and another 200 mm (7.9 in) in the rear. Then, like all great engineering teams, the group has looked to nature for inspiration and incorporated the 'Dragonfly' * – an insect-shaped patch of carbon fiber bonded to the chassis. Its wingspan and abdomen radically improve torsional stiffness at one of the critical points in the body structure between the middle floor and rear construction. The result is dramatic: +45% increase in torsional stiffness in the chassis structure.

*A cleverly shaped patch of CFRP bonded to the steel underbody stiffens the traditionally weak interface between the middle floor and the rear structure. At Polestar, this component is known as the Dragonfly.

Bonding with the material

When asked what is was like to work with the carbon fiber on the project, Zef had this to say:

"One of the main challenges was to get to know the material. We wanted the perfect solution for Polestar 1 and were prepared to do whatever it took to find it. We've learned a lot and, even if everything didn't go exactly the way we expected, you often learn more from the surprises. The process has resulted in a very high level of precision and finish."

Once they'd familiarized themselves with the material, the Polestar engineers set about defining and controlling all the other parameters – these included critical decisions such as which fiber and resin to use, along with how to assemble and paint the various sections.

The team also learned how to define the material for computer-aided engineering (CAE) calculations so that they could test and evaluate the parts. They also knew from experience that carbon fiber behaved differently depending on directional forces. So draping simulations were done to anticipate what the material would do in reality.

And the advantage of all this clever modeling? The directional weaves in the material are now specifically placed in the car to counteract forces and increase strength during different driving conditions.

We were expecting big numbers from the car in terms of performance and small numbers in terms of dimensions and weight. So there's been a lot of research, analysis, testing and also a bit of head scratching along the way. The car is a massive 230 kg (507 lbs) lighter by integrating the material into the underbody, which completely neutralizes the added weight of the batteries.

Impressive.

Realizing the design

The design concept and execution is very important for any brand. As Polestar 1 was the first car to emerge from the Polestar stable, it was crucial to make a statement and visualize the brand's design language.

According to Zef, the material doesn't really play a big role initially. It's later, when it comes to surfacing and integration of details, that the differences become obvious. Carbon fiber takes the design to a whole new level. Restrictions, such as press depth, are suddenly no longer an issue. That means the designers can create much more dramatic surfaces – or more flat ones if they want.

"If we had been working with steel," adds Zef, "then the hood surfacing would be far less dramatic than it is. Now we've been able to create the car more like a sculpture and create sharper edges on the feature lines – that makes the car look more technical and refined."

He continues: "With carbon fiber in low-volume production, a lot of things can be done by hand. So you can always find solutions, you can talk to the supplier and do things differently to arrive at the right result. Proportions and stance are always really important in any design and we are obviously very pleased with the result."

Painting carbon fiber is completely different from painting steel. Getting the right color and finish has meant challenging the team to achieve perfection.

What's on the surface counts

Such an exclusive and expensive material requires expertise and craftsmanship throughout every stage of the process. When it comes to painting the new Polestar 1, there's been a lot of experimenting and practice.

"Every car designer knows exactly what to do - and what not to do to - when they create a car in steel," says Zef. "But this is something else. Almost everything is possible."

But painting carbon fiber is completely different from painting steel. All the parts arrive from the supplier coated with a primer and to getting the right color and finish has meant challenging the team to achieve perfection.

And the same goes for the quality control. Where hawk-eyed, highly skilled people once scanned for the smallest imperfections in color or finish, they found those issues didn't exist in painted carbon fiber. They're now looking for completely different quality issues. As with all things at Polestar, the ambition is high, and everyone is continually pushing to find the perfect way to work with the material.

When safety is part of performance

Polestar has performed extensive testing in order to secure the rigorous demands on safety and durability of the Polestar 1. Assembling the carbon fiber parts with the steel platform and the other parts of the Polestar 1 is challenging. Steel is more elastic than carbon fiber and in order to fasten the two materials, Polestar uses specially developed adhesive that can handle the variation in movement from the steel and carbon fiber parts. Zef explains:

"The challenge is that carbon fiber is a linear brittle material and traditional automotive structures normally use materials that get deformed before breaking (like steel for example). Carbon fiber, on the other hand, behaves in different ways depending on the direction of the forces."

The end result makes the Polestar 1 a car with world-leading attributes in crash safety and durability. Merging the carbon fiber body with the steel platform provides the Polestar 1 with the best of both worlds, in terms of driving characteristics and safety.

Reflecting on the details

Looking back on the work so far, carbon fiber makes a strong case for itself. It's definitely high-tech, still requires a dedicated amount of crafting and there's a fair amount of patience involved in getting it absolutely right. But when you do, there is a feeling of bespoke, precision engineering and design sophistication that is impossible to ignore. Your perspective changes. You run your hands over the car and know that the surfaces are not pressed in tools by machines, that the carbon patches are each placed by hand and because of that, you know the pattern lines match up. You also know each part is finished off manually and with obsessive detail. Put all this together and it's a very special feeling.

Every carbon patch is placed by hand to make sure the pattern lines up and every part is also finished off manually.

Will we see more use of carbon fiber in the future? It's a tough question to answer and there are many parameters that must be decided before a team can make that decision, but one thing is certain: There are lots of places that are ideally suited to carbon fiber in cars and the advantages are worth it. If its use becomes more commonplace, it's good to know that suppliers are also looking at ways to recycle and re-use the material in the future. Something that is a critical factor in using the material on Polestar 1.

So did the team find the right balance and stay true to the Polestar philosophy: no compromise, no shortcuts?

It would appear that they did… and then some.

Carbon fiber is one of our cutting-edge technologies. There are many more.

Polestar 1 is an Electric Performance Hybrid, an exclusive car that pairs electrification with outstanding performance, gorgeous proportions, exquisite craftsmanship and innovative technology. Every piece is developed and chosen with care. The use of carbon fiber is just one area that demonstrates how serious we are about making Polestar 1 a car without compromise.

Fast facts – Carbon fiber and Polestar 1:

- 1.Weight. A total saving of -230 kg (507 lbs) using carbon fiber together with the SPA chassis.

- 2.Stiffness. Increased torsional stiffness from 22 N/mm2 to 32 N/mm2 (3191 to 4641 psi). That's +45%.

- 3.Center of Gravity. A steel SPA floor + carbon fiber upper lowers the center of gravity for superior handling and performance.